In today’s competitive manufacturing landscape, companies are constantly looking for ways to reduce costs while maintaining high-quality production standards. One effective strategy that has gained popularity is investing in used 700 CNC (Computer Numerical Control) machining equipment. While purchasing new machinery might seem like the obvious choice, used CNC machines offer several compelling advantages that make them an attractive option for many businesses, especially those in industries like aerospace where precision and efficiency are paramount.

Cost-Effectiveness Without Compromise

The most immediate and apparent benefit of investing in used 700 CNC machining equipment is cost savings. New CNC machines are a significant investment, often requiring substantial capital outlay. However, by choosing used equipment, businesses can acquire high-quality machines at a fraction of the cost. This allows companies to allocate their resources more effectively, investing in other critical areas of their operations, such as research and development, employee training, or expanding production capabilities.

Moreover, the depreciation rate of new machinery is steep. The moment a new CNC machine is purchased and installed, its value begins to decline rapidly. In contrast, used machines have already undergone the bulk of their depreciation, meaning the investment retains its value more effectively over time. This not only reduces the initial purchase cost but also minimizes the potential financial loss if the equipment needs to be resold in the future.

Proven Reliability and Performance

Another advantage of opting for used 700 CNC machines is the opportunity to acquire proven and reliable equipment. New machines, while technologically advanced, may come with unforeseen issues that can disrupt production and lead to costly downtime. Used machines, on the other hand, have already been tested in real-world manufacturing environments. Their reliability and performance have been established, providing peace of mind that they can meet the rigorous demands of production.

Furthermore, many used CNC machines have undergone refurbishment or reconditioning processes, ensuring they are in excellent working condition. These machines are often equipped with the latest software updates and may include additional features that enhance their functionality, making them a cost-effective solution for businesses seeking to optimize their production processes without sacrificing quality.

Faster Return on Investment

Investing in used 700 CNC machining equipment also offers the advantage of a quicker return on investment (ROI). Since the initial purchase price is lower, companies can recover their investment more rapidly through increased production efficiency and reduced operational costs. This accelerated ROI is particularly beneficial for small to medium-sized enterprises (SMEs) that may have limited financial resources but still require high-quality machinery to compete effectively in the market.

Versatility and Flexibility

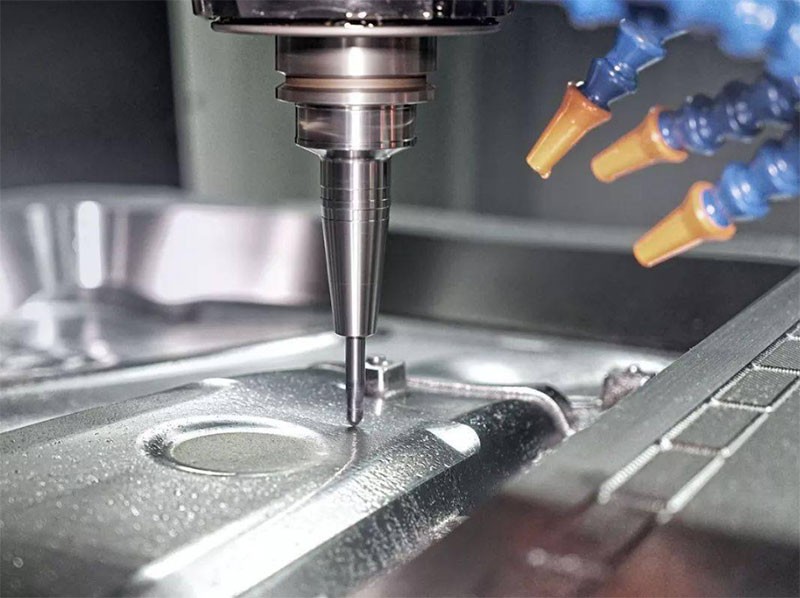

Used CNC machines, especially the 700 series, are known for their versatility and flexibility. These machines can be easily adapted to different production needs, making them ideal for businesses that require a wide range of machining capabilities. Whether it’s for milling, drilling, or turning, a used 700 CNC machine can handle various tasks with precision and efficiency, providing a valuable asset to any manufacturing operation.

In industries such as aerospace, where the demand for precision and reliability is paramount, CNC machining for aerospace plays a crucial role. By investing in used 700 CNC machining equipment, businesses can meet these stringent requirements without the need for exorbitant expenditure on new machinery.

Conclusion

In conclusion, investing in used 700 CNC machining equipment is a smart and strategic decision for businesses looking to cut costs without cutting corners. The cost savings, proven reliability, faster ROI, and versatility make used CNC machines an attractive option for manufacturers across various industries. By choosing used equipment, companies can enhance their production capabilities, remain competitive, and achieve long-term success in an ever-evolving market.